描述

The core advantage of expandable container houses is the ultimate optimization of space, balancing “small transportation footprint” and “ample usable space”: when transported or idle, it is a compact single unit of 18㎡ (same as a 20-foot container), with lower transportation and storage costs than traditional temporary buildings; when in use, the two sides are expanded by mechanical/hydraulic systems, instantly expanding the indoor area by 1.5-2 times to 30-40㎡, with no column partitions, allowing for flexible division of functional areas and accommodation of kitchens and bathrooms.

Why is the expandable container house the market’s first choice?

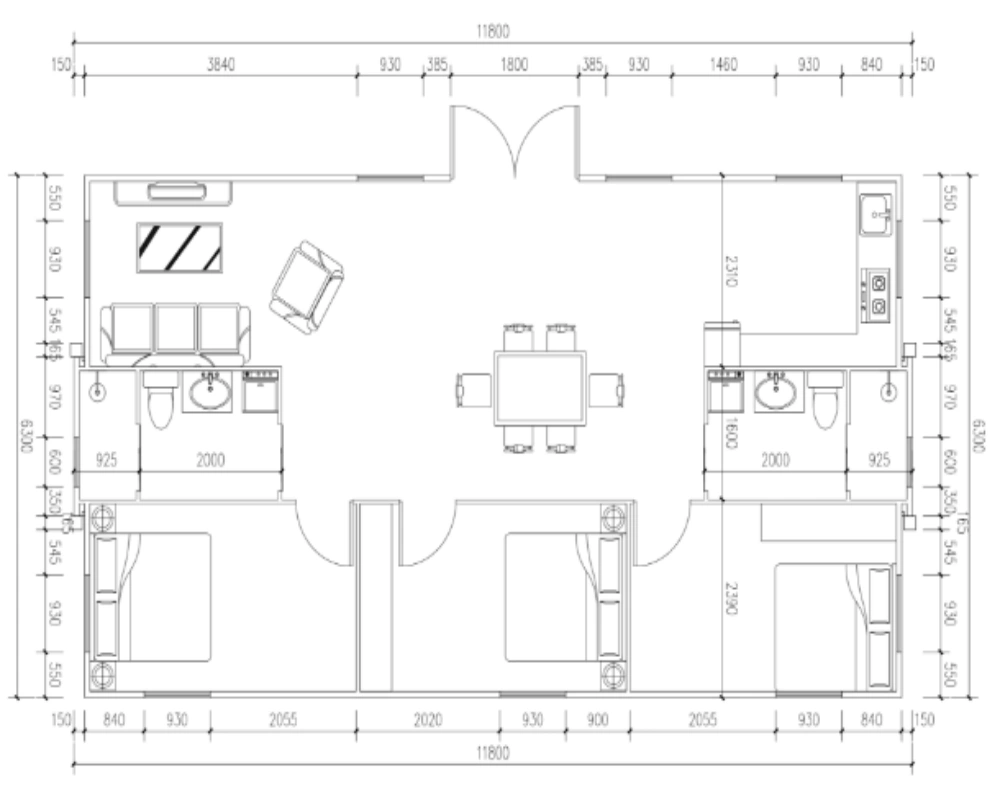

| Product specifications | External dimension (mm) | 5900*6300*2480 |

| Internal dimension (mm) | 5460*6140*2240 | |

| Folding state(mm) | 5900*2200*2480 | |

| Main body frame | Top side rail | 80*100*2.5mm galvanized square pipe |

| Top beam | Galvanized bending parts 2.5mm | |

| Top longitudinal secondary beam | 30*30*1.3mm galvanized square pipe | |

| Top transverse secondary beam | 40*60*1.5mm galvanized square pipe | |

| Bottom side beam | 80*100*2.5mm galvanized square pipe | |

| Bottom end beam | Galvanized bend 2.5mm thick | |

| Bottom longitudinal secondary beam | 40*80*1.5mm galvanized square pipe | |

| Bottom transverse secondary beam | 40*80*1.5mm galvanized square pipe | |

| 6mm galvanized hanger | Galvanized hanging head L210*W150*H160mm | |

| Steel column | Galvanized bend 2.5mm thick |

- Controllable cost: The unit area cost is 60% lower than that of brick-concrete buildings. And the can be recovered after reuses.

- Ecological advantage: Recyclable materials are used. And the carbon emissions of the whole cycle are only 1/3 of those of traditional buildings.

- Scenario empowerment: As a portable shipping container house, it supports the rapid implementation of 20+ application scenarios. Such as mining camps, cultural and tourism homestays, and post-disaster reconstruction.

🏠Rapid Setup—Move In the Same Day

Our prefabricated houses undergo meticulous pre-processing throughout the entire process before leaving the factory: each independent unit is professionally wired according to standardized designs, pre-installed with water supply and drainage pipes conforming to building codes (including complete pipelines for water supply, drainage, and sewage, with sealed interfaces), and precisely reserved dedicated interfaces for HVAC systems (compatible with heating, cooling, and ventilation equipment of different power ratings, with uniform interface specifications, eliminating the need for on-site secondary drilling and adjustment).

This integrated prefabricated house design completely breaks away from the traditional “on-site stacking” construction model, bringing you an extremely efficient and seamless installation experience: from unit transportation to the site, only basic positioning and module assembly are required, followed by direct connection to utilities such as water, electricity, gas, and internet. The entire process is clear, simple to operate, and truly achieves the convenience of “same-day setup, same-day connection, and same-day move-in.”

English

English